Why Your R638 Audit for Your Food Company in South Africa is likely to Fail: Risks Traditional Cleaning Can't Effectively Solve

Why Your R638 Audit for Your Food Company in South Africa is likely to Fail: Risks Traditional Cleaning Can't Effectively Solve

Why Your R638 Audit for Your Food Company in South Africa is likely to Fail: Risks Traditional Cleaning Can't Effectively Solve

Nervous and Anxious about your next R638 Audit at your Food Manufacturing Facility?

If you haven't Adopted Dry Steam Technology with Your Facility yet, then you Should be ..

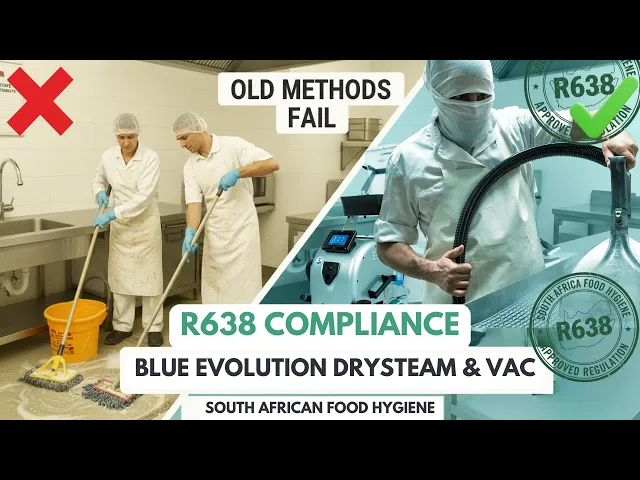

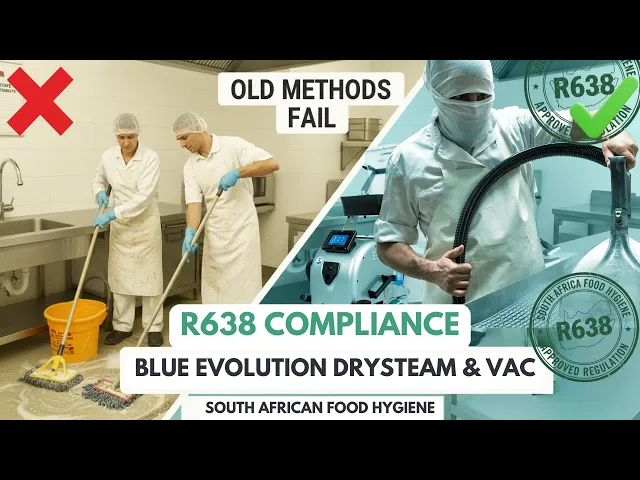

If you're a food facility manager in South Africa, here's a sobering reality: your bucket-and-mop cleaning routine might be the very thing sabotaging your next R638 inspection. While your team scrubs diligently every night, invisible bacterial colonies are thriving in the microscopic crevices of your production floor—and traditional cleaning methods are powerless to reach them.

The cost of non-compliance with Regulation R638 isn't just financial. It's reputational damage, potential shutdowns, and in worst-case scenarios, public health crises that destroy businesses overnight. Yet across South Africa's food industry, managers continue relying on cleaning methods that haven't fundamentally changed in decades.

It's time for a paradigm shift.

The R638 Compliance Crisis Nobody's Talking About

Regulation R638, promulgated under the Foodstuffs, Cosmetics and Disinfectants Act, sets the legal benchmark for hygiene on food premises in South Africa. The regulation is unequivocal: all surfaces must be kept "clean"—defined as free from soil, dust, grease, and microorganisms—to a state where hygiene is truly attained.

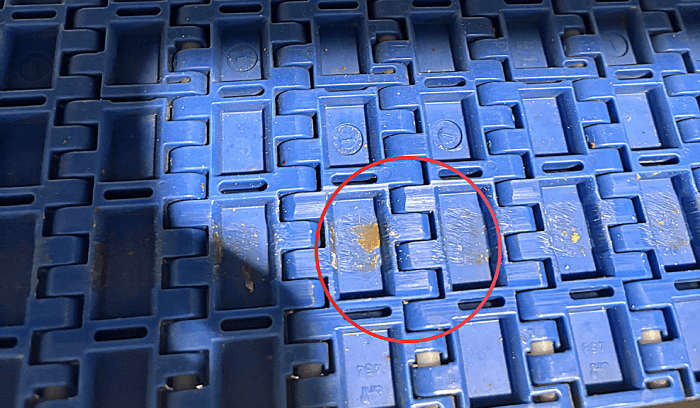

Here's the problem: most food facilities believe they're compliant because their floors look clean. But "looking clean" and "being hygienically clean" are two completely different standards under R638.

Consider what happens during a typical cleaning shift with traditional methods:

Mop water becomes contaminated after the first few passes, effectively spreading bacteria rather than eliminating it

Chemical detergents leave invisible residue films that can contaminate food products

Water pools create breeding grounds for Listeria and other pathogens

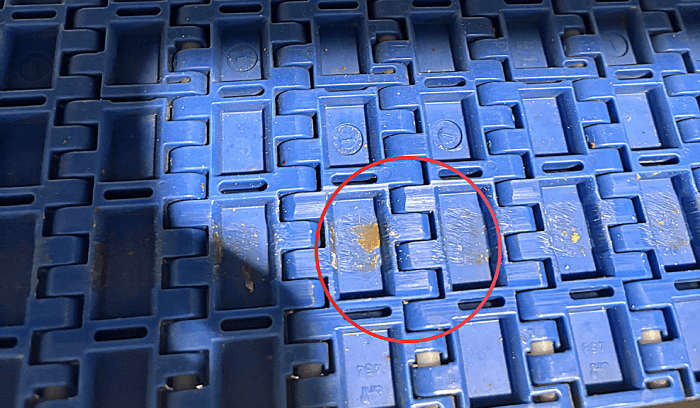

Grout lines, equipment seams, and microscopic crevices remain untouched

Cross-contamination occurs as dirty water splashes from low-care to high-care zones

The inspectors know this. They're looking for these exact failures during audits.

Enter Dry Steam: The Technology That Changes Everything

Blue Evolution Drysteam machines represent a fundamental breakthrough in food facility hygiene—and they were engineered specifically with regulations like R638 in mind. These aren't just "better cleaning machines." They're compliance systems that address every critical pain point that traditional methods fail to resolve.

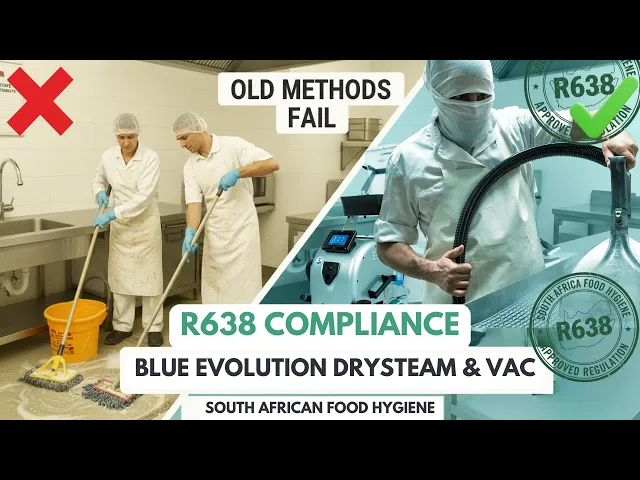

The Science Behind Superior Sanitation

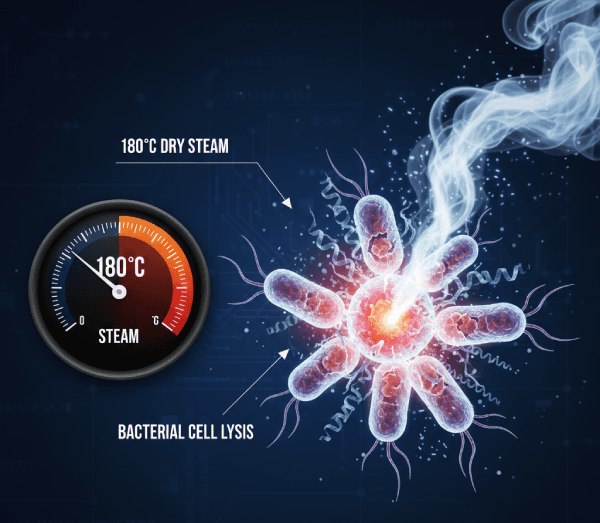

At the heart of the Blue Evolution system is 180°C dry steam delivered at 10 bar pressure. To understand why this matters, think about what happens to bacteria at this temperature: their cellular proteins literally denature and "cook." There's no adaptation, no resistance development—just complete thermal destruction.

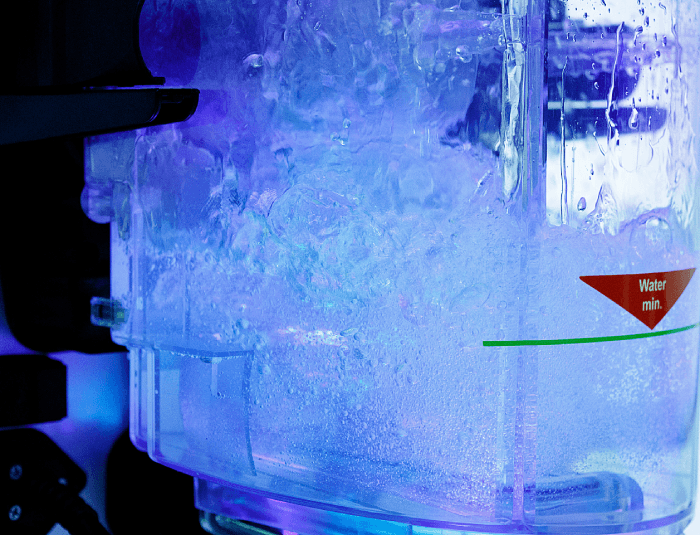

But here's what makes it revolutionary: this steam contains only 5-7% water content. Traditional steam cleaners flood surfaces with moisture. Blue Evolution's "Drysteam" technology delivers devastating heat with minimal water, meaning surfaces dry almost instantly—typically within seconds.

For R638 compliance, this solves one of the regulation's most stringent requirements: preventing dampness that promotes mold and bacterial growth, particularly Listeria monocytogenes, which thrives in wet environments.

The Triple-Threat Sanitation System

What truly sets Blue Evolution apart is the integration of three powerful technologies in one HACCP-certified system:

1. Pressurized Dry Steam (180°C at 10 Bar)

The high-pressure steam penetrates microscopic crevices in stainless steel equipment, tile grout, and floor joints where bacteria colonies establish themselves. Traditional scrubbing can't reach these spaces—the bristles are too large, and the mechanical action too weak. The Blue Evolution system delivers thermal sanitation exactly where pathogens hide.

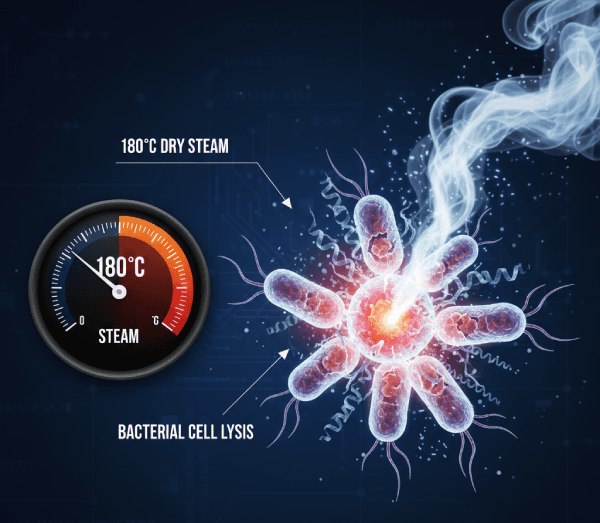

2. Integrated Vacuum and Water Filtration

This is the compliance game-changer. Instead of rinsing contaminated water across your floor—where it can splash onto walls, equipment legs, and be tracked into high-care zones—the Blue Evolution machine extracts loosened grime immediately into its internal filtration system, leaving most surfaces immediately dry.

This directly addresses R638's prohibition against practices that may cause food contamination by biological agents. You're not just cleaning; you're containing and removing contamination in real-time.

3. UVC Light Sanitation

Here's where Blue Evolution becomes genuinely next-generation. The built-in UVC light system doesn't just enhance the cleaning process—it deactivates the DNA of bacteria and viruses collected in the waste tank, including E. coli and Salmonella. This ensures that the air exhausted by the vacuum is purified, and the waste water doesn't become a biohazard breeding ground inside the machine itself.

Think about that: with traditional methods, your mop bucket becomes one of the most contaminated items in your facility.

The Compliance Comparison: Traditional vs. Blue Evolution

Let's examine the stark reality of how each method addresses R638's core requirements:

Microbial Control

Traditional Method: Chemical sanitizers that bacteria can develop resistance to over time, requiring increasingly stronger concentrations that risk chemical contamination of food products.

Blue Evolution: 180°C thermal destruction combined with UVC light sanitation—a two-stage kill mechanism that eliminates pathogens without chemicals and prevents any possibility of antimicrobial resistance.

Surface Residue

Traditional Method: Detergent films remain on surfaces even after rinsing, creating a chemical contamination risk explicitly prohibited under R638.

Blue Evolution: Zero chemicals—only purified water vapor, leaving absolutely no residue that could contaminate food products.

Water Usage and Safety

Traditional Method: High water volume creates slip hazards, requires extensive drying time, and risks splashing contaminated water into clean zones.

Blue Evolution: Uses 93% less water than traditional methods, with surfaces drying in seconds, virtually eliminating slip hazards and cross-contamination risks.

Reaching Hidden Areas

Traditional Method: Manual scrubbing cannot physically access equipment seams, grout lines, and microscopic surface irregularities where biofilms establish.

Blue Evolution: 10-bar pressure steam penetration reaches areas impossible to clean manually, destroying biofilms at their source.

The Record-Keeping Advantage

R638 requires that the "Person in Charge" maintain detailed cleaning schedules and sanitation records. Compliance audits scrutinize these records intensely—and inconsistent or incomplete documentation is one of the most common reasons for citations.

The Blue Evolution S+ model features an LCD or touchscreen display with automated maintenance alerts . This technology transforms compliance documentation from a burdensome administrative task into an automated system that:

Alerts operators to required maintenance before equipment effectiveness degrades

Includes a patented descaling system ensuring the machine operates at peak performance continuously

Meets Regulation 7's "Standards for Equipment" by remaining reliably functional without downtime

For facility managers, this means confidence during audits. You can demonstrate not just that cleaning occurred, but that it met the required standards every single time.

The Real Cost of Non-Compliance

Before dismissing advanced sanitation technology as "too expensive," consider the actual cost of traditional methods:

A single failed R638 inspection can result in:

Production shutdowns costing thousands per day

Mandatory product recalls destroying entire inventory batches

Reputational damage that takes years to rebuild

Legal liability if contaminated products cause illness

Loss of contracts with major retailers who require certified suppliers

Meanwhile, traditional cleaning requires:

Continuous chemical purchases

Higher water and sewage costs

More labour hours due to slow drying times

Frequent equipment replacement (mops, buckets that become contamination sources)

Additional slip-and-fall liability insurance

When you calculate the true cost, Blue Evolution's return on investment becomes clear—particularly when you factor in the avoided costs of compliance failures.

Future-Proofing Your Facility

South African food safety regulations are only becoming more stringent, not more lenient. Global food chains operating in South Africa are implementing standards that exceed minimum R638 requirements. Consumer awareness of food safety is at an all-time high, and social media amplifies every contamination incident instantly.

The question isn't whether to upgrade your sanitation protocols—it's when, and whether you'll do it proactively or reactively after a costly compliance failure.

Blue Evolution Drysteam technology isn't just about passing your next inspection. It's about building a foundation of genuine food safety that protects your brand, your customers, and your business's future.

Take Action Now

If you're responsible for food safety compliance in your facility, ask yourself honestly: can your current cleaning methods withstand the scrutiny of a detailed R638 audit? Can you prove that you're achieving true hygiene, not just surface-level cleanliness?

The gap between "looking clean" and "being compliant" has never been more consequential. Blue Evolution Drysteam machines don't just help you meet R638 requirements—they exceed them, providing defensible, documented proof that your facility maintains the highest standards of food safety.

Your next R638 audit is coming. Will you be ready?

For more information about Blue Evolution Drysteam technology and R638 compliance solutions tailored to your facility, contact www.drysteam.co.za Distributors of Blue Evolution in Southern Africa. We will gladly arrange for a demo in Gauteng or Cape Town. Don't wait for a failed inspection to discover that traditional cleaning isn't enough.

About Blue Evolution Dry Steam Technology

Blue Evolution represents the next generation of HACCP-certified sanitation systems, combining patented dry steam technology with integrated vacuum extraction and UVC light sanitation. Designed specifically for food production facilities, healthcare environments, and other high-hygiene applications, Blue Evolution machines deliver superior sanitation while reducing water usage by up to 93% and eliminating chemical contamination risks. All models are built to meet and exceed international food safety standards, including South Africa's R638 regulation.

Made in Italy and German Engineered

Nervous and Anxious about your next R638 Audit at your Food Manufacturing Facility?

If you haven't Adopted Dry Steam Technology with Your Facility yet, then you Should be ..

If you're a food facility manager in South Africa, here's a sobering reality: your bucket-and-mop cleaning routine might be the very thing sabotaging your next R638 inspection. While your team scrubs diligently every night, invisible bacterial colonies are thriving in the microscopic crevices of your production floor—and traditional cleaning methods are powerless to reach them.

The cost of non-compliance with Regulation R638 isn't just financial. It's reputational damage, potential shutdowns, and in worst-case scenarios, public health crises that destroy businesses overnight. Yet across South Africa's food industry, managers continue relying on cleaning methods that haven't fundamentally changed in decades.

It's time for a paradigm shift.

The R638 Compliance Crisis Nobody's Talking About

Regulation R638, promulgated under the Foodstuffs, Cosmetics and Disinfectants Act, sets the legal benchmark for hygiene on food premises in South Africa. The regulation is unequivocal: all surfaces must be kept "clean"—defined as free from soil, dust, grease, and microorganisms—to a state where hygiene is truly attained.

Here's the problem: most food facilities believe they're compliant because their floors look clean. But "looking clean" and "being hygienically clean" are two completely different standards under R638.

Consider what happens during a typical cleaning shift with traditional methods:

Mop water becomes contaminated after the first few passes, effectively spreading bacteria rather than eliminating it

Chemical detergents leave invisible residue films that can contaminate food products

Water pools create breeding grounds for Listeria and other pathogens

Grout lines, equipment seams, and microscopic crevices remain untouched

Cross-contamination occurs as dirty water splashes from low-care to high-care zones

The inspectors know this. They're looking for these exact failures during audits.

Enter Dry Steam: The Technology That Changes Everything

Blue Evolution Drysteam machines represent a fundamental breakthrough in food facility hygiene—and they were engineered specifically with regulations like R638 in mind. These aren't just "better cleaning machines." They're compliance systems that address every critical pain point that traditional methods fail to resolve.

The Science Behind Superior Sanitation

At the heart of the Blue Evolution system is 180°C dry steam delivered at 10 bar pressure. To understand why this matters, think about what happens to bacteria at this temperature: their cellular proteins literally denature and "cook." There's no adaptation, no resistance development—just complete thermal destruction.

But here's what makes it revolutionary: this steam contains only 5-7% water content. Traditional steam cleaners flood surfaces with moisture. Blue Evolution's "Drysteam" technology delivers devastating heat with minimal water, meaning surfaces dry almost instantly—typically within seconds.

For R638 compliance, this solves one of the regulation's most stringent requirements: preventing dampness that promotes mold and bacterial growth, particularly Listeria monocytogenes, which thrives in wet environments.

The Triple-Threat Sanitation System

What truly sets Blue Evolution apart is the integration of three powerful technologies in one HACCP-certified system:

1. Pressurized Dry Steam (180°C at 10 Bar)

The high-pressure steam penetrates microscopic crevices in stainless steel equipment, tile grout, and floor joints where bacteria colonies establish themselves. Traditional scrubbing can't reach these spaces—the bristles are too large, and the mechanical action too weak. The Blue Evolution system delivers thermal sanitation exactly where pathogens hide.

2. Integrated Vacuum and Water Filtration

This is the compliance game-changer. Instead of rinsing contaminated water across your floor—where it can splash onto walls, equipment legs, and be tracked into high-care zones—the Blue Evolution machine extracts loosened grime immediately into its internal filtration system, leaving most surfaces immediately dry.

This directly addresses R638's prohibition against practices that may cause food contamination by biological agents. You're not just cleaning; you're containing and removing contamination in real-time.

3. UVC Light Sanitation

Here's where Blue Evolution becomes genuinely next-generation. The built-in UVC light system doesn't just enhance the cleaning process—it deactivates the DNA of bacteria and viruses collected in the waste tank, including E. coli and Salmonella. This ensures that the air exhausted by the vacuum is purified, and the waste water doesn't become a biohazard breeding ground inside the machine itself.

Think about that: with traditional methods, your mop bucket becomes one of the most contaminated items in your facility.

The Compliance Comparison: Traditional vs. Blue Evolution

Let's examine the stark reality of how each method addresses R638's core requirements:

Microbial Control

Traditional Method: Chemical sanitizers that bacteria can develop resistance to over time, requiring increasingly stronger concentrations that risk chemical contamination of food products.

Blue Evolution: 180°C thermal destruction combined with UVC light sanitation—a two-stage kill mechanism that eliminates pathogens without chemicals and prevents any possibility of antimicrobial resistance.

Surface Residue

Traditional Method: Detergent films remain on surfaces even after rinsing, creating a chemical contamination risk explicitly prohibited under R638.

Blue Evolution: Zero chemicals—only purified water vapor, leaving absolutely no residue that could contaminate food products.

Water Usage and Safety

Traditional Method: High water volume creates slip hazards, requires extensive drying time, and risks splashing contaminated water into clean zones.

Blue Evolution: Uses 93% less water than traditional methods, with surfaces drying in seconds, virtually eliminating slip hazards and cross-contamination risks.

Reaching Hidden Areas

Traditional Method: Manual scrubbing cannot physically access equipment seams, grout lines, and microscopic surface irregularities where biofilms establish.

Blue Evolution: 10-bar pressure steam penetration reaches areas impossible to clean manually, destroying biofilms at their source.

The Record-Keeping Advantage

R638 requires that the "Person in Charge" maintain detailed cleaning schedules and sanitation records. Compliance audits scrutinize these records intensely—and inconsistent or incomplete documentation is one of the most common reasons for citations.

The Blue Evolution S+ model features an LCD or touchscreen display with automated maintenance alerts . This technology transforms compliance documentation from a burdensome administrative task into an automated system that:

Alerts operators to required maintenance before equipment effectiveness degrades

Includes a patented descaling system ensuring the machine operates at peak performance continuously

Meets Regulation 7's "Standards for Equipment" by remaining reliably functional without downtime

For facility managers, this means confidence during audits. You can demonstrate not just that cleaning occurred, but that it met the required standards every single time.

The Real Cost of Non-Compliance

Before dismissing advanced sanitation technology as "too expensive," consider the actual cost of traditional methods:

A single failed R638 inspection can result in:

Production shutdowns costing thousands per day

Mandatory product recalls destroying entire inventory batches

Reputational damage that takes years to rebuild

Legal liability if contaminated products cause illness

Loss of contracts with major retailers who require certified suppliers

Meanwhile, traditional cleaning requires:

Continuous chemical purchases

Higher water and sewage costs

More labour hours due to slow drying times

Frequent equipment replacement (mops, buckets that become contamination sources)

Additional slip-and-fall liability insurance

When you calculate the true cost, Blue Evolution's return on investment becomes clear—particularly when you factor in the avoided costs of compliance failures.

Future-Proofing Your Facility

South African food safety regulations are only becoming more stringent, not more lenient. Global food chains operating in South Africa are implementing standards that exceed minimum R638 requirements. Consumer awareness of food safety is at an all-time high, and social media amplifies every contamination incident instantly.

The question isn't whether to upgrade your sanitation protocols—it's when, and whether you'll do it proactively or reactively after a costly compliance failure.

Blue Evolution Drysteam technology isn't just about passing your next inspection. It's about building a foundation of genuine food safety that protects your brand, your customers, and your business's future.

Take Action Now

If you're responsible for food safety compliance in your facility, ask yourself honestly: can your current cleaning methods withstand the scrutiny of a detailed R638 audit? Can you prove that you're achieving true hygiene, not just surface-level cleanliness?

The gap between "looking clean" and "being compliant" has never been more consequential. Blue Evolution Drysteam machines don't just help you meet R638 requirements—they exceed them, providing defensible, documented proof that your facility maintains the highest standards of food safety.

Your next R638 audit is coming. Will you be ready?

For more information about Blue Evolution Drysteam technology and R638 compliance solutions tailored to your facility, contact www.drysteam.co.za Distributors of Blue Evolution in Southern Africa. We will gladly arrange for a demo in Gauteng or Cape Town. Don't wait for a failed inspection to discover that traditional cleaning isn't enough.

About Blue Evolution Dry Steam Technology

Blue Evolution represents the next generation of HACCP-certified sanitation systems, combining patented dry steam technology with integrated vacuum extraction and UVC light sanitation. Designed specifically for food production facilities, healthcare environments, and other high-hygiene applications, Blue Evolution machines deliver superior sanitation while reducing water usage by up to 93% and eliminating chemical contamination risks. All models are built to meet and exceed international food safety standards, including South Africa's R638 regulation.

Made in Italy and German Engineered

Milnerton,

Cape Town

South Africa

021 2000 224 (Office)

083 2293907 (Kelly)

sales@drysteam.co.za

ABOUT US

© 2024 DRYSTEAM. All rights reserved.

© 2024 DRYSTEAM. All rights reserved.

Milnerton,

Cape Town

South Africa

021 2000 224 (Office)

083 2293907 (Kelly)

sales@drysteam.co.za

ABOUT US

© 2024 DRYSTEAM. All rights reserved.